Remote Performance Management (RPM)

Achieve safer, more sustainable, and more efficient operations with proactive data gathering across the oil and gas enterprise.

Benefits and Capabilities of RPM

Low Cost, Cloud-Based Solution

Collect and access historical, real-time, and predictive data in the cloud to keep critical operations running and gain access to business insights. Store different types of data in different ways and prioritize how data is queried.

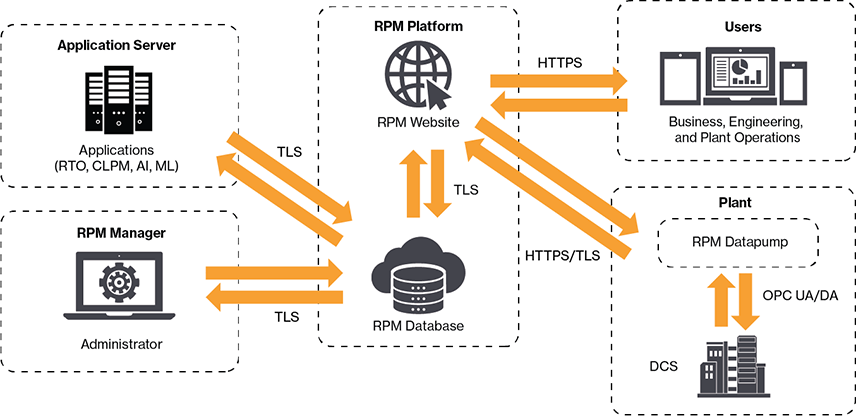

Secure Remote Access

Enables secure remote access to operational data for internal users and third-party vendors either through a cloud service or on-premise deployment.

Custom Reports & Dashboards

Create custom reports and views to monitor processes and identify issues quickly. Compare downtime events and batch datasets to identify patterns and replicate best practices.

Operational Agility

Securely send data to the cloud for collaboration among engineers, plant operators, and on-site analysis. Deliver analysis-ready operations data to AI tools and machine-learning algorithms to derive new insights.

Common Applications

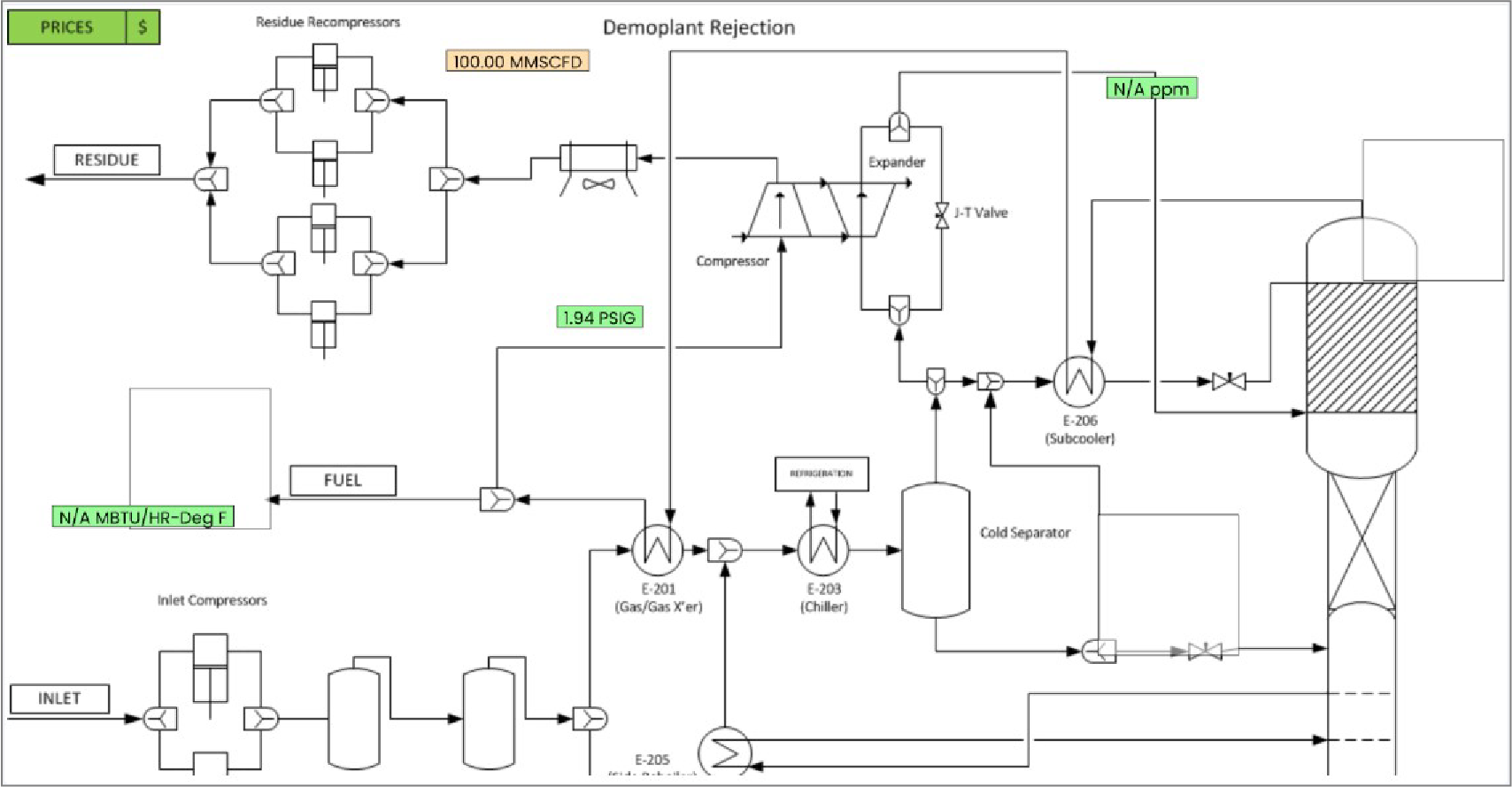

Process Optimization

Use open-loop or closed-loop real-time optimization (RTO) to provide real-time feedback to plant operators and recommend optimal performance targets. Use browser-based reporting to enable operations staff to determine how best to adjust process operations, given current process economics and constraints, to maximize uptime and profitability.

Plant Performance Management

Develop and monitor performance metrics for assets under different operating conditions. Examine past operational modes and events, and improve operations based on this data.

Control Loop Performance Monitoring (CLPM)

Monitor the performance of industrial process control loops to detect and identify under-performing loops and to help diagnose control loop problems.

Data encryption systems encode your information so that only authorized parties can access it

Provides secure user authentication using either encrypted PRM user credentials or the corporate Active Directory. Using the corporate active directory simplifies RPM maintenance by having corporate IT maintain the user access list.

Secure User Authentication

Provides secure user authentication using either encrypted PRM user credentials or the corporate Active Directory. Using the corporate active directory simplifies RPM maintenance by having corporate IT maintain the user access list.

TLS and HTTPS Protocols

- TLS uses the more secure Key-Hashing for Message Authentication code (HMAC) to ensure that a record cannot be altered during transmission over an open network.

- TLS provides more specific alerts about problems with a session and documents when certain alerts are sent.

- HTTPS secures your data in transit and protects your website from data breaches.

OPC UA/DA

- Gives applications across the manufacturing enterprise access to real-time plant-floor information in a consistent manner, making multi-vendor interoperability and plug-and-play connectivity a reality.

- Removes barriers between traditionally proprietary factory-floor devices, systems, and other manufacturing software.

- Delivers additional business benefits in the form of increased flexibility and reduced system integration, development, and installation costs of factory automation and process control systems.

- Open industry standard for manufacturing because its members share a common vision – to create a worldwide industry standard for connectivity and interoperability across the manufacturing enterprise.

"The [eSimulation] project resulted in a software tool that Crosstex can use to manage its business and to strategically address mid-stream challenges.”

Rodney Madden

VP Marketing and Supply

Crosstex Energy Services LP

"*" indicates required fields